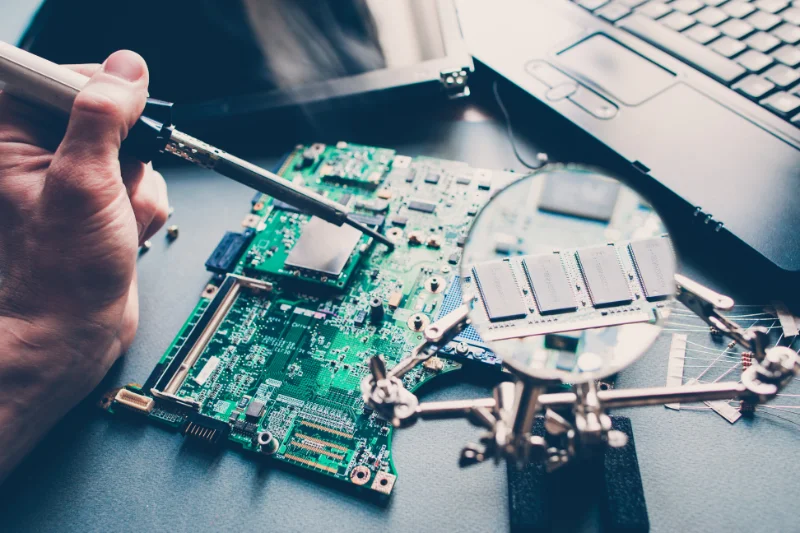

Your Trusted HDI PCB Manufacturer

GCS has the capabilities and experience to take on all jobs — including high density interconnect (HDI) fabrication. HDI PCBs have become increasingly popular and are used in a wide variety of industries.

State-of-the-art facilities and leading HDI PCB manufacturer with deep engineering experience with most sophisticated production and testing equipment, we can handle the most complex HDI projects.

![]()

HDI Technology Capabilities

| Feature | Mass Production | Small batch | Sample |

| Max Layer count | 18L(for system HDI) | 20L(for system HDI) | 22L(for system HDI) |

| 12L(for any layer) | 14L(for any layer) | 14L(for any layer) | |

| HLC+HDI | Plus4 | Plus4 | Plus4 |

| Min Micro-via Size | 3mil | 3mil | 3mil |

| Min Micro-via Depth | 1.5~3.0mil | 1.5~3.0mil | 1.5~3.0mil |

| Micro-via PAD Size | D+6 | D+5 | D+4 |

| Micro-via A/R | 0.7:1 | 0.8:1 | 0.8:1 |

| Min Hole wall to Hole wall spacing | 14mil | 12mil | 12mil |

| Laser dielectric | FR4 | FR4 | FR4 |

| HCL+HDI+GF | Yes | Yes | Yes |

| Copper Filled Microvia | Yes | Yes | Yes |

| RoHs Certification &Green material | Yes | Yes | Yes |

| Impedance Control | ±10% | ±10% | ±8% |

| Hybrid Construction | FR4 hybrid | FR4 hybrid | High speed +FR4 hybrid |

| Materials | Std. FR4, High Tg FR4, TUC, Shengyi, Iteq, Panasonic, Ventec, Nelco, Isola, Rogers, Dupont, Arlon | ||

| Standards | IPC6012, IPC-2226 | ||

![]()

Applications for High Density Interconnect PCBs

High-Density Interconnect (HDI) printed circuit boards are a specialized type of PCB known for their compact design and increased circuit density. HDI PCBs are used in various applications where space constraints, signal integrity, and miniaturization are critical.

- Smartphones and Mobile Devices: HDI PCBs are widely used in smartphones, tablets, and wearables to accommodate a multitude of components within a small, slim form factor. They enable the high functionality of modern mobile devices.

- Laptop and Desktop Computers: In computers, HDI PCBs are used to create compact motherboards, enhancing performance and power efficiency while reducing the overall size of the devices.

- Data Storage Devices: In solid-state drives (SSDs) and hard disk drives (HDDs), HDI PCBs are employed to manage complex controller chips and memory, ensuring fast data access and reliability.

- Telecommunications Equipment: HDI PCBs are used in network switches, routers, and communication devices to provide high-speed signal routing and compact layouts for efficient data transmission.

- Medical Devices: Medical equipment like MRI machines, CT scanners, and monitoring devices use HDI PCBs to maintain precision and compact design, especially in portable diagnostic equipment.

- Automotive Electronics: HDI PCBs are used in advanced driver-assistance systems (ADAS), infotainment systems, and engine control units (ECUs) to save space and enhance performance in vehicles.

- Aerospace: In avionics systems, radar technology, HDI PCBs enable high signal integrity in a compact, lightweight form to meet the demands of the aerospace industry.

- Consumer Electronics: HDI PCBs are found in gaming consoles, home entertainment systems, and high-definition displays, providing efficient signal routing and compact designs for these devices.

- Wearable Technology: Wearable devices, including smartwatches, fitness trackers, and augmented reality glasses, utilize HDI PCBs to optimize functionality and minimize size and weight.

- Industrial Automation: In industrial control systems and automation equipment, HDI PCBs enable compact designs and high-speed signal routing for precise control and monitoring.

- RF and Microwave Applications: HDI PCBs are used in RF (radio frequency) and microwave applications, such as RF amplifiers and signal processing, to maintain signal integrity and reduce interference.

- Test and Measurement Equipment: High-performance test and measurement devices, including oscilloscopes and spectrum analyzers, use HDI PCBs to ensure high precision and signal fidelity.

- Robotics: In robotics applications, HDI PCBs enable the integration of sensors, control systems, and communication components in compact, high-performance designs.

Get A Quote

HDI PCBs play a critical role in modern electronics, enabling the development of smaller, more powerful, and highly functional electronic devices in a wide range of industries. Their compact and dense design allows engineers and designers to push the boundaries of technology while meeting the needs of today’s demanding applications.

Request A Quote